How to remove air bubbles from epoxy? Get started with these 5 tips

Air bubbles in epoxy are undesirable. Fortunately, you can prevent and fix this with the right skills. Read the best tips & tricks from Resin Art experts for successfully removing or preventing air bubbles from epoxy.

1. Mix epoxy well and let it rest for a while

One of the main causes of air bubbles in epoxy is the poor mixing of the two components. Make sure that the epoxy resin and hardener are at room temperature and that you mix them gently for at least 2-3 minutes . Always mix in one direction, this prevents a lot of air bubbles . After this, wait 15-25 minutes before pouring and you will see that most of the bubbles have already been drawn to the surface and have burst. Then pour the epoxy gently.

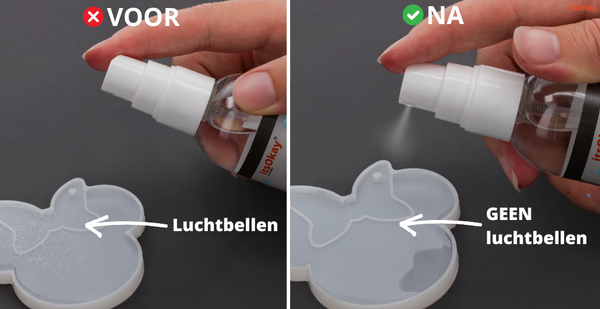

2. Use a bubble spray

With a bubble spray specifically for epoxy and polyester you can quickly and effectively remove epoxy air bubbles . The Bubble Blaster is a safe and effective spray against air bubbles. Spray once over the epoxy and your artwork is bubble-free. Applicable to any size mold, table or object.

3. Pour epoxy in layers

First apply a thin layer of epoxy of maximum 1 cm and let it harden before applying the next layer. This ensures that air bubbles can burst from the first layer before the next layer is applied. Do this especially when working with porous surfaces such as wood, stone or other natural products. The air contained in these will rise to the top.

4. Use a burner or heat gun

One way to remove air bubbles from epoxy casting resin is to use a torch (lighter) or heat gun . Gently move the torch or heat gun over the surface of the epoxy to pop any air bubbles. This is a great technique if you are casting into a wooden frame or have applied a coating.

However, this is definitely not preferred if you are pouring into a silicone mold. If you still want to use this method, be careful not to touch the edges of the silicone mold, otherwise they will melt to the epoxy. This can ruin your artwork.

5. Heat epoxy in a bain-marie

Preheating the epoxy can also help prevent air bubbles. Place the cup of mixed epoxy in a container of warm water (around 50-60 degrees) for 10 minutes to reduce the viscosity and pop the air bubbles. Make sure you cup stands firmly and cannot tip over.

6. Use a degasser or vacuum pump

A degasser or vacuum air release kit is a very effective way to remove air bubbles in epoxy casting resin. Place your epoxy artwork in a special degasser or vacuum pump to remove 100% of the air from the mixture. The investment is the only disadvantage: these devices cost already quickly 300-600 euros. However, if you work with epoxy often, this can be a smart investment. This way you can remove air bubbles from epoxy again and again for all your artwork.

More information?

Do you have questions about making art, jewelry or casting/coating floors or other objects? At itsOkay we have several epoxy experts each with their own expertise. We are happy to help you.

Contact the itsOkay customer service or take a look at the Epoxy knowledge center .